Installation, Testing & Maintenance of New and Existing Systems

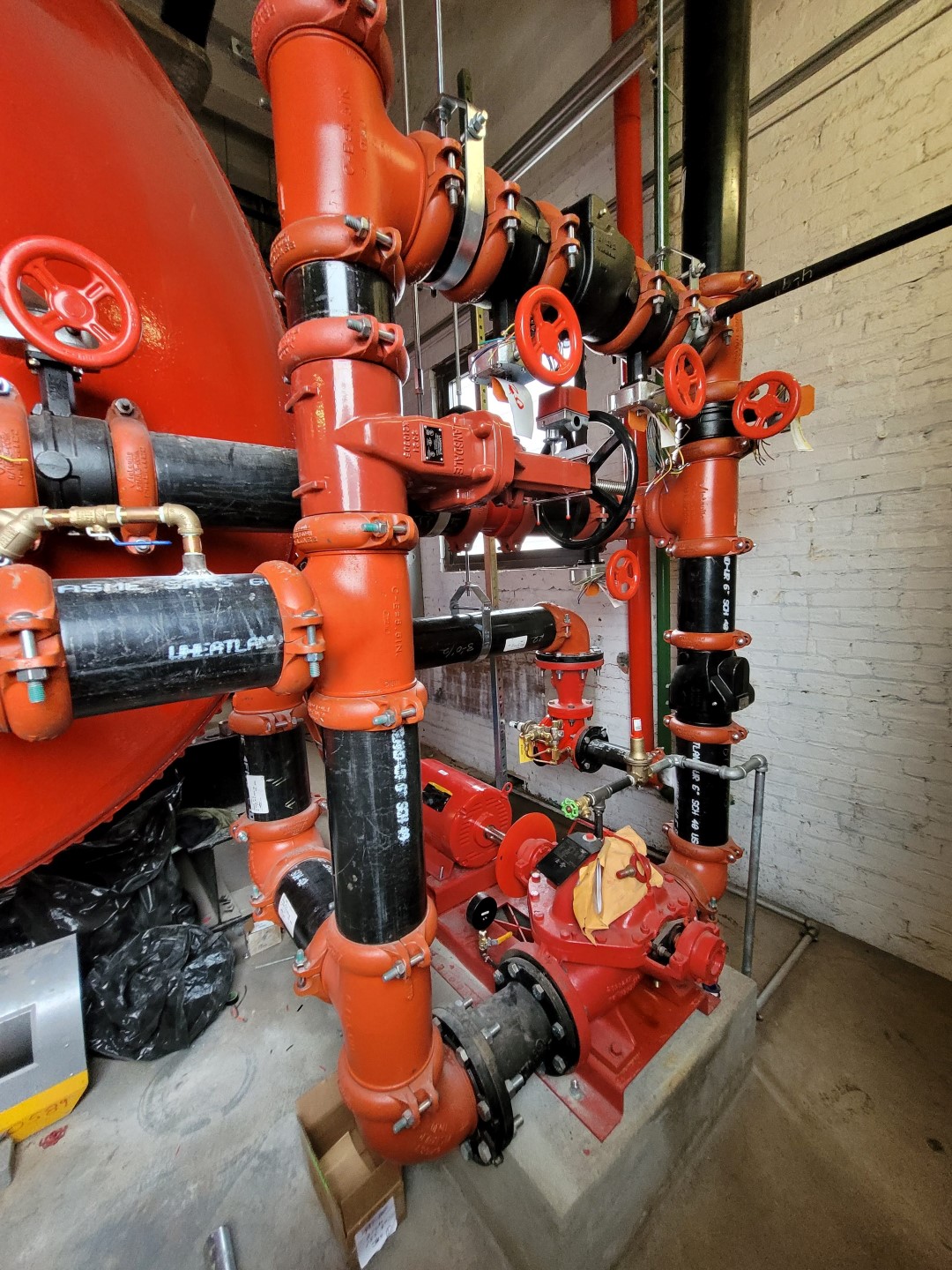

Installation and Maintenance:

- Wet Sprinkler Systems

- Dry Systems

- Pre-Action Systems

- Deluge Systems

- Waterless/Clean Agent Systems

Inspection and Testing to Comply with Regulatory Requirements:

- Fire Standpipe Systems

- Cure FDNY or NYC DOB Violations

- FDNY Testing: Annual, 3-Year and 5-Year

- NFPA 25 Testing and Compliance

- Local Law Compliance- LL26 of 2004

Par Fire Protection, a division of The Par Group specializes in installing and testing sprinkler systems as well as modifying existing systems. We also perform maintenance on all sprinkler devices.

We assist our clients with NFPA 25 compliance – Inspection, Testing & Maintenance of water-based fire protection systems.

We have also worked with property owners and managers to ensure their buildings are in observance of Local Law 26 of 2004– Sprinkler Compliance.

A wet sprinkler system is a sprinkler system using automatic sprinkler heads attached to a piping system containing water and is connected to a water supply so that water releases immediately from sprinklers opened by heat from a fire.

The dry-pipe sprinkler system employs automatic sprinklers attached to a piping system containing air or nitrogen under pressure. When released, the water flows into the piping system and discharges only from those sprinklers which have been activated by the fire. Dry-pipe sprinkler systems are installed in lieu of wet-pipe systems where piping is subject to freezing.

Pre-action fire sprinkler systems employ the basic concept of a dry pipe system in that water is not normally contained within the pipes. The difference, however, is that water is held from piping by an electrically operated valve, known as a pre-action valve.

Valve operation is controlled by independent flame, heat, or smoke detection. This feature provides an added level of protection against inadvertent discharge. For this reason, pre-action systems are frequently employed in water sensitive environments such as archival vaults, fine art storage rooms, rare book libraries and computer centers.

A deluge fire sprinkler system is similar to a pre-action system except the sprinkler heads are open and the pipe is not pressurized with air. Deluge systems are connected to a water supply through a deluge valve that is opened by the operation of a smoke or heat detection system. The detection system is installed in the same area as the sprinklers. When the detection system is activated water discharges through all of the sprinkler heads in the system.

Deluge systems are used in places that are considered high hazard areas such as power plants, aircraft hangars and chemical storage or processing facilities. Deluge systems are needed where high velocity suppression is necessary to prevent fire spread.

Using water to extinguish a fire is not always the ideal choice. While sprinklers can often save buildings, they will also likely permanently damage high-value electronic, computer and IT equipment.

A waterless system is made up of a clean agent liquid material stored in pressurized cylinders. The material flows through a piping network to a discharge nozzle where it is deployed as a gas in a fire situation. Clean Agent/Waterless Fire Suppression Systems are used to protect facilities containing valuable corporate assets, equipment and software.

Fire standpipe systems are an arrangement of piping, valves hose connections and associated equipment installed in a building or structure, with fire hose connections located in such a manner that water can be discharged through attached hose and nozzles, for the purpose of extinguishing a fire.